One of my latest gadgets is the MakerBot Replicator 2 3D printer. There is a lot to learn and to say about the Replicator 2, so this will not really be a review so much as a set of first impressions and observations. I plan to follow up with additional information after I’ve had more time to play with it.

The Replicator 2 is one of the latest devices that will make 3D printing accessible to a wider audience. At the most basic level, a 3D printer is a device that builds up an object by adding precise layers one on top of each other. If you remember dot matrix printers, picture the printer continually printing on the same line more and more ink until the ink is visibly taller than the page. The Replicator 2 and other entry-level 3D printers do that with some type of plastic. The plastic is on a spool which they unwind, melt, and extrude through a printer head with great precision. A few folks have told me that it reminds them of how an arc welder works using metal instead of plastic.

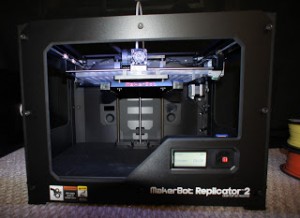

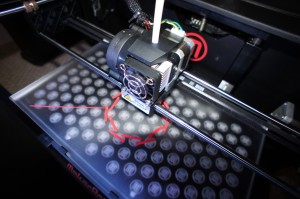

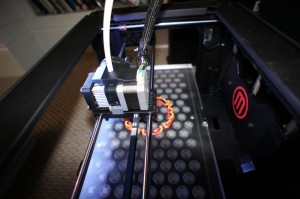

The device is about the size of a small microwave oven. It has a set of belts that move its printer head in two dimensions and the ability to raise and lower the platform on which it is building the object. It is both fascinating and amazing to watch the 3D printer slowly build up an object, a fraction of a millimeter at a time. I tried capturing it on video, but it takes quite a while to see anything noticeable. Instead, I’ve included a few pictures to try and give a sense of what happens.

Over the last month, I’ve been able to find enough time to make a few items. I started off with the built-in test patterns. These are really easy to create after the straightforward task of setting up the device. You load a spool of PLA plastic filament and pick one of the five samples from the LCD console on the front of the device. The picture farther down shows some of these items including a chain (10 minutes), a bracelet (15 minutes), a nut and bolt (25 minutes) and a comb (10 minutes).

These items each illustrate some interesting characteristics of what the Replicator 2 can make. The comb has the typical flexibility you would expect of comb, but does not seem particularly brittle. The plastic bracelet is fairly thin such that the flex of the plastic combined with the layout allows the bracelet to stretch so it can go over your hand to put it on. The chain is very cool because of the precision the Replicator 2 uses as it builds up the links. Each link is built up at about a 45-degree angle to the platform. Adjacent links are at 90-angles to each other and offset just enough so they do not touch. The nut and bolt match and can screw together. The threads were slightly off, however, so it was a bit hard to turn.

Once I tried all the built-in sample patterns, I tried some experiments. I changed the colors of an object mid-print (see the “Irish” bracelet). It is fairly easy to pause a print, unload the current filament spool, and load a new one in a different color.

I then tried using patterns I downloaded from Thingiverse. Thingiverse is a Web site where people with 3D printers can share 3D patterns for things they’ve designed. I found and printed a bird napkin ring pattern based on a Bakelite one I had when I was growing. It took about 40 minutes, and though it was not quite like the one I had as a child, it did bring back some fond memories.

I have not spent any time trying to create my own patterns, but I was able to print a small treasure chest from a pattern that my son Nathan created using an online CAD program.

While I really have enjoyed playing with the Replicator 2, I do have some complaints. One of them is the limited set of colors of PLA filament available from MakerBot. For example, they don’t sell blue, gray or black, let alone pink! I’ve ordered some third-party pink filament to see how well it works.

Another complain is that too much about the whole process of 3D printing relies on lore rather than manuals and tutorials. You will not start making things without a lot of time learning, reading forums, and experimenting. A 3D printer is the ultimate tinkerer’s device. If you just want a few Legos, buy them at the store. The current generation of 3D printers is such that you will spend a lot of time designing, trying things out, and just plain failing. If you like doing that kind of thing, you will love the Replicator 2. If not, you will probably find yourself frustrated.

A closely related issue is that it is hard to know whether something will work or not. I’ve had mixed luck at best downloading patterns from Thingiverse. One pattern was for a chain like the built-in one, but with the links in a circle like a bracelet. That is what the earlier pictures showed being printed. It turned out that the links were too large, so that when the Replicator 2 tried to create the top of the links, the plastic sagged. This quickly led to a mess of plastic rather than a link bracelet. The problem there seemed to be that the pattern was for a different kind of 3D printer or a different kind of plastic. I tried a more traditional solid bracelet, but instead of starting out with an open ring in the shape of the bracelet, it filled the bottom in creating a disk. My guess is that this pattern was for different printing software.

I also tried printing a piece of Duplo-compatible railroad track. It was doing really well and was over 80% complete, when I encountered a new problem. The six-inch long piece of track began to warp which caused the ends, and eventually the whole piece, to pull up from the platform. At that point, the print head starting moving the track around and creating a mess. As best I can tell, warping on larger pieces is a known problem, though supposedly less so with the new PLA than with earlier ABS plastic filament. There are some techniques that supposedly may help that I will need to look into.

The state of 3D printer reminds me of the early days of laser printers. In the early 1980s, we had an Imagen laser printer that cost thousands of dollars. I think its list price was $7,000 or $10,000, but the university probably got it at a discount. (The original Apple LaserWriter was the first laser printer under $5,000, a few years later in 1985.) When we got that early laser printer, there were no word processing programs like Word. Instead, there were text editors. In order to control where on the page the text would appear and how it should look, you needed programs like Runoff, TRoff, and Scribe. They used commands somewhat like HTML to format the page. So, you might have a command like @i(text to print in italics) in your document. The most precise, and complex, such program was Donald Knuth’s TeX. TeX is supposed to be rendered not with a lowercase e, but with an E descending halfway below the line of text. In those days, being able to do that was a sign you were a hardcore laser printer user. Knuth also wrote Metafont for creating your own fonts. I admit to spending a decent bit of time tuning the kerning and ligatures of fonts. Again, the hardcore folks spent lots of times debating things like that. I was only a dabbler, but I was very interested in such things.

The whole area is what became known as desktop publishing. Today, there really is no such thing. We expect to be able to print whatever we choose to format on our screens. The software and hardware makes that all possible. We now just think of it as printing. The same transformation will happen over the next few years in 3D printing.

The Replicator 2 is not cheap at $2,199, but compared to the early laser printers it is much more accessible. In addition, plastic filament runs about $40 per spool. A spool is a kilogram and should make a decent bit of stuff, but that is quite a bit of money for some plastic! Despite that price and the frustrations of making things work, I really like the MakerBot Replicator 2. It allows me to be on the forefront of 3D printing, an area that is going to take off. As the devices get cheaper and more sophisticated, we will all become makers as we all became desktop publishers.

Now, if I could just figure out how to make a white, red, and pink bracelet before Valentine’s Day!