I’ve had my Makerbot Replicator 2 for over a year now and have learned quite a bit since I wrote my initial review. While the 3D printer itself is still the same, the whole 3D printing ecosystem has improved. I’m generally optimistic about 3D printing, but concede a lot needs to happen before it can succeed with the general public.

Makerbot the company has made real progress in the last year. They’ve announced new 3D printers. And, they’ve done simple things like adding more colors of PLA filament The additional colors may seem trivial, but I consider it important. I wanted to make something in pink, so I bought filament elsewhere. It came on a different size spool, which was a hassle to deal with. Certainly, you can get filament cheaper or in more colors elsewhere, but the key to the broader success of 3D printing will be for the hassles to diminish.

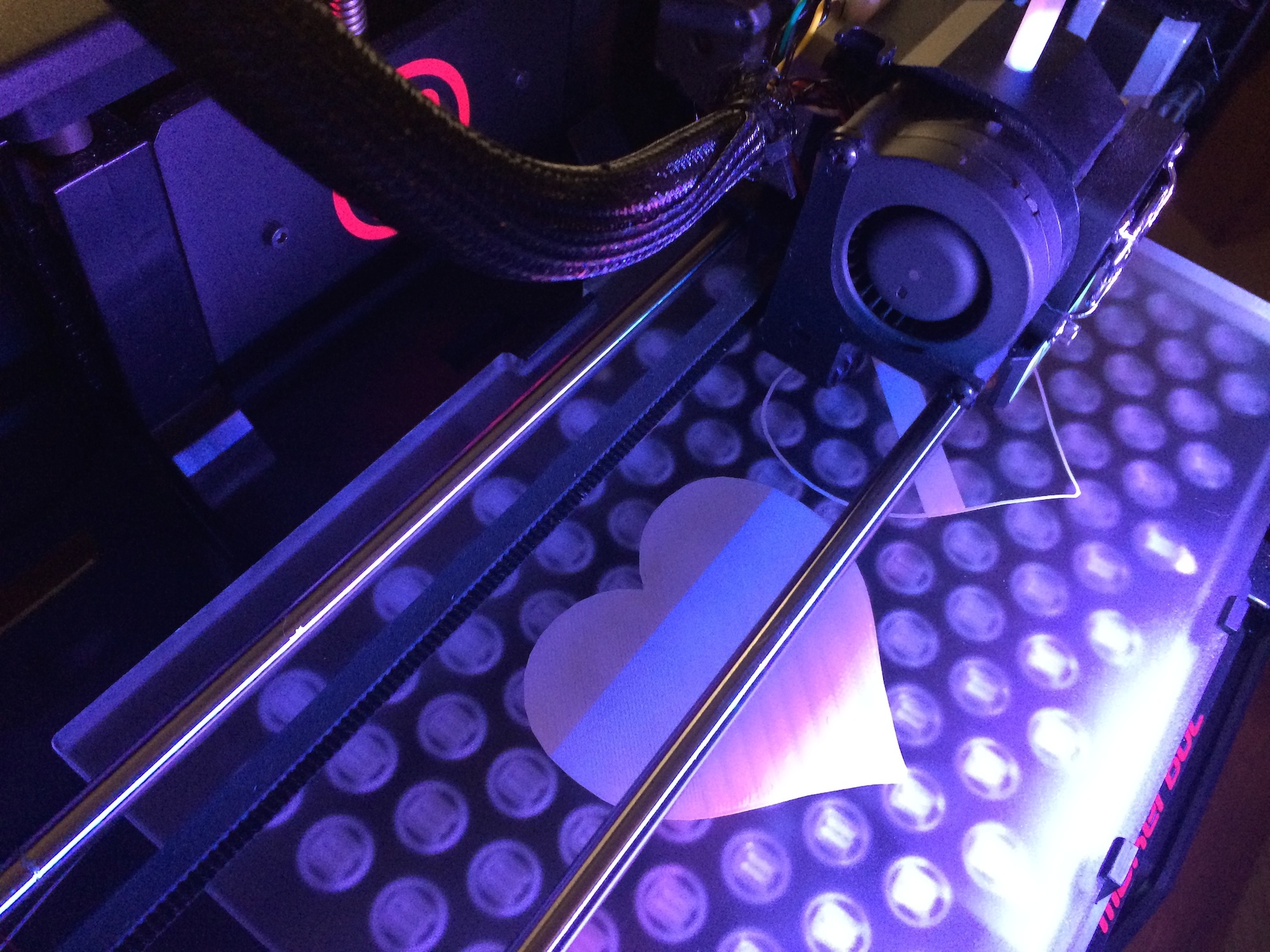

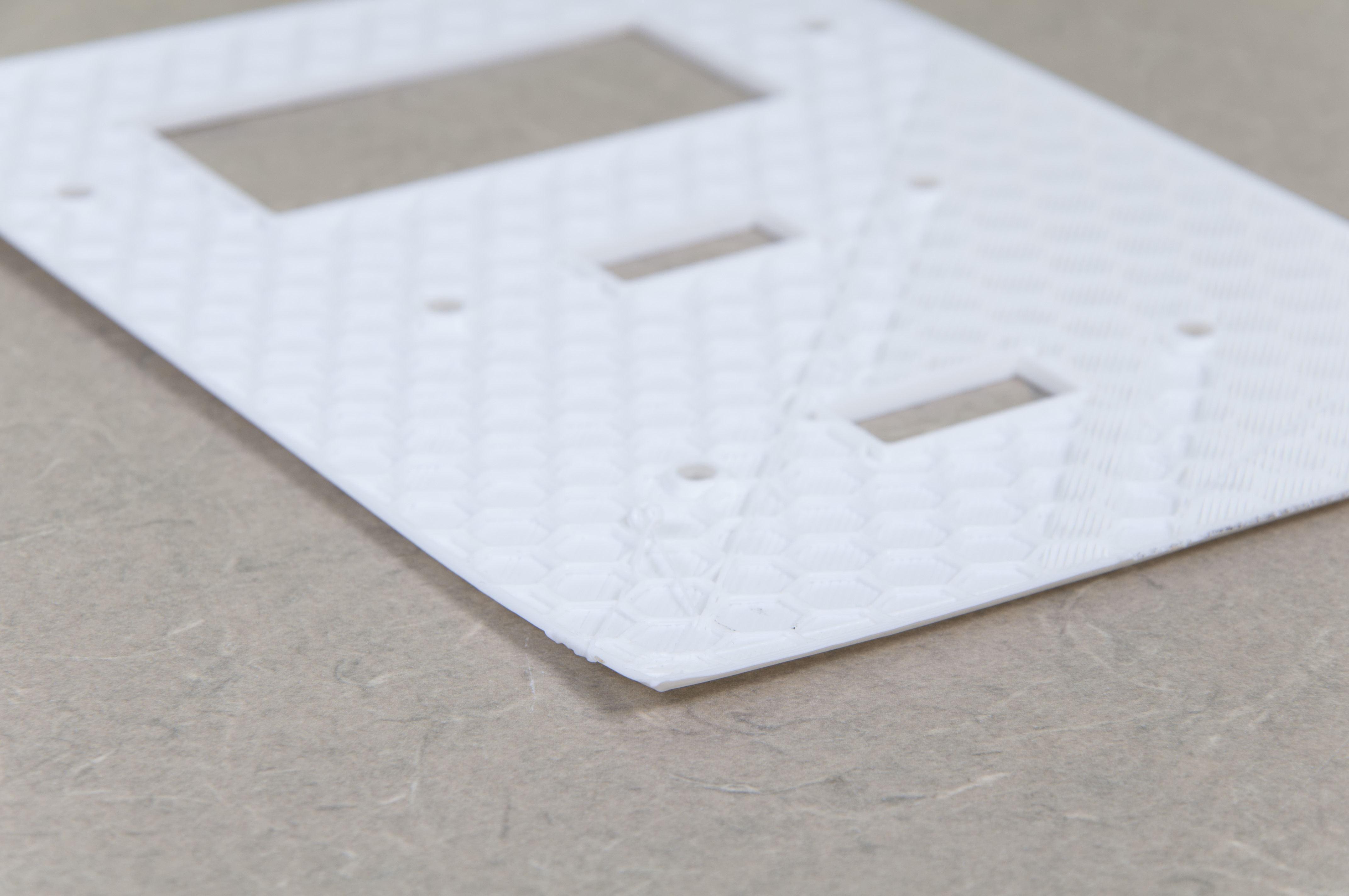

Thingiverse and the patterns on it have also improved considerably. I find myself downloading working patterns more often than not. And, I tend to print useful things rather than just cute things. For example, I needed an odd light switch cover to accommodate my new WeMo smart light switch. My local hardware store did not carry such a plate. I checked on Thingiverse and found WALLY, the wall plate customizer. WALLY won one of Thingiverse’s contests with this truly useful tool. Basically, it allows you to create a wide variety of customized wall plates. I was able to make my custom plate that day.

Once I got started, I could not stop. I made all sorts of simple covers in different colors. A red one for my office, a blue one for Mark’s, and a pink one for my daughter’s. Fortunately for other folks, I eventually got tired of my efforts to brighten up everyone’s walls with these colorful wall plates.

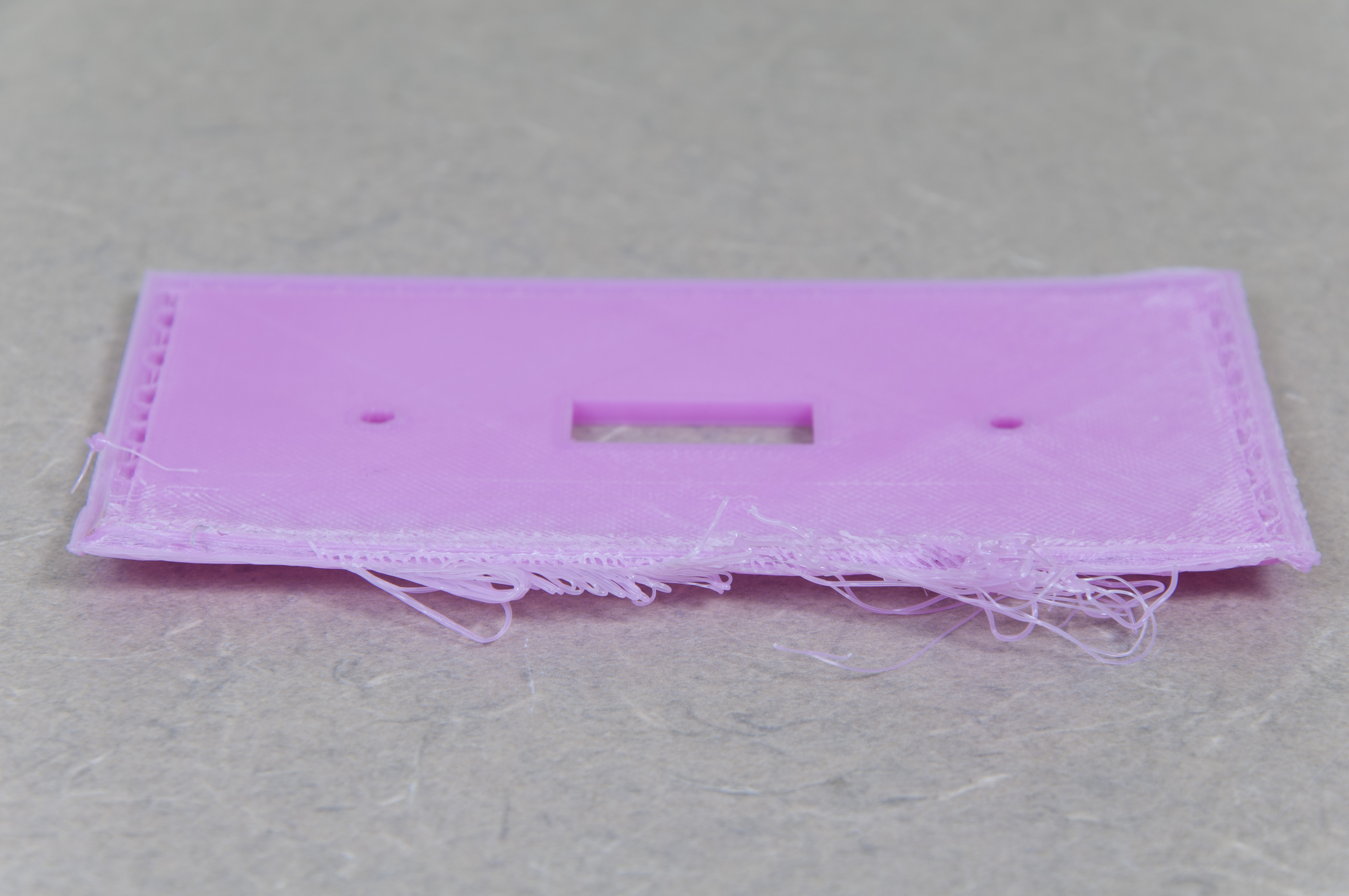

As with any new technology, I’ve encountered some problems along the way. I was printing out yet another custom light switch cover when I ran into one of those issues that make it clear that 3D printing still has a ways to go. The cover was a large one and it started to warp. I was not watching the print, but was nearby. I heard the print head start to bang into the warped model and before I could stop the printer, I heard a piece of metal bounce off the platform. It was an inch-long metal tube. I never did figure out what it was, and the printer seems none the worse for wear.

Another thing that makes the 3D printer a challenge for the general public and a joy for hacker/designers is the ability to modify designs to your needs. For example, I moved to a new office and got a glass whiteboard. Unfortunately, it did not come with anything to hold my markers or eraser. I looked on Thingiverse and found a whiteboard marker holder that didn’t quite work on my whiteboard. So, I modified it.

I used OpenSCAD to modify the pattern. Once I got it working, I cleaned up some bugs from the original version, parameterized it so it could work easily for both erasers and markers, and, in the spirit of the maker culture, I put my derivative creation on Thingiverse so others could use it. It was neat to see that other folks looked at it and made their own holders. I’m not sure exactly why, but I really like the thought that someone else may have in their office a physical creation that I designed.

To give an idea of how simple something like this can be, here is the complete OpenSCAD code for the marker tray. Click here to see the fewer than 30 lines of code (about half of which are blank lines and closing brackets).

Along with these issues, you have typical hardware problems. Prints sometimes fail. Some objects get stuck on the platform. (I expect that eventually I’m going to cut off one of my fingers by using a sharp tool to remove prints from the platform.) Sometimes, I have trouble removing a spool of plastic from the print head or getting a new one properly fed in. Picture everything that you’ve ever had go wrong in a laser printer and then expand that from two dimensions to three and you can begin to imagine the problems.

Despite these hassles, I am still excited about 3D printing and look forward to more experimentation. In fact, we even bought one for folks at PT to play with and they have been learning lots. I’ll let you know about some of their experiences in the near future.

My bottom line is that if you have the opportunity to play with 3D printing, you should. It is the future and it is always an adventure to get there before most people!